Performance Characteristics

-

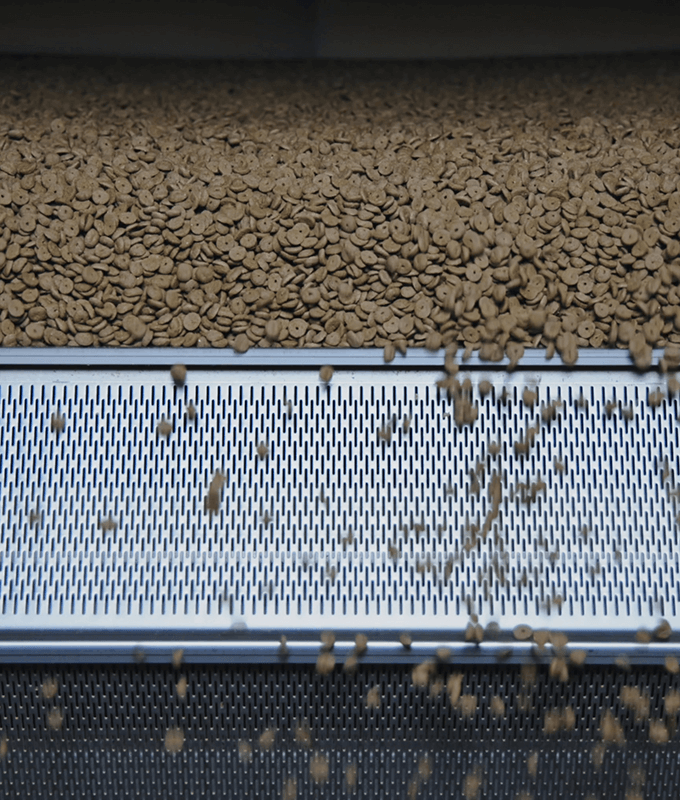

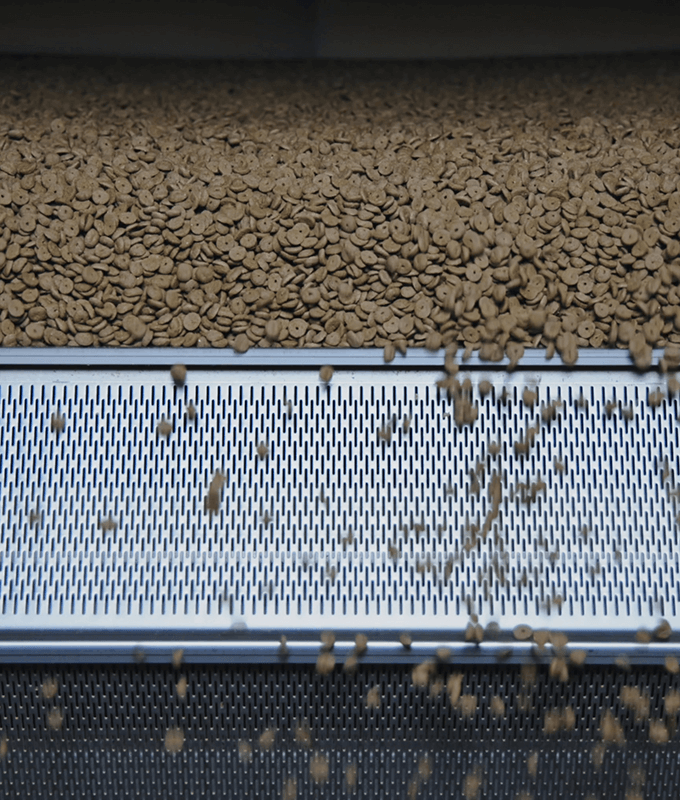

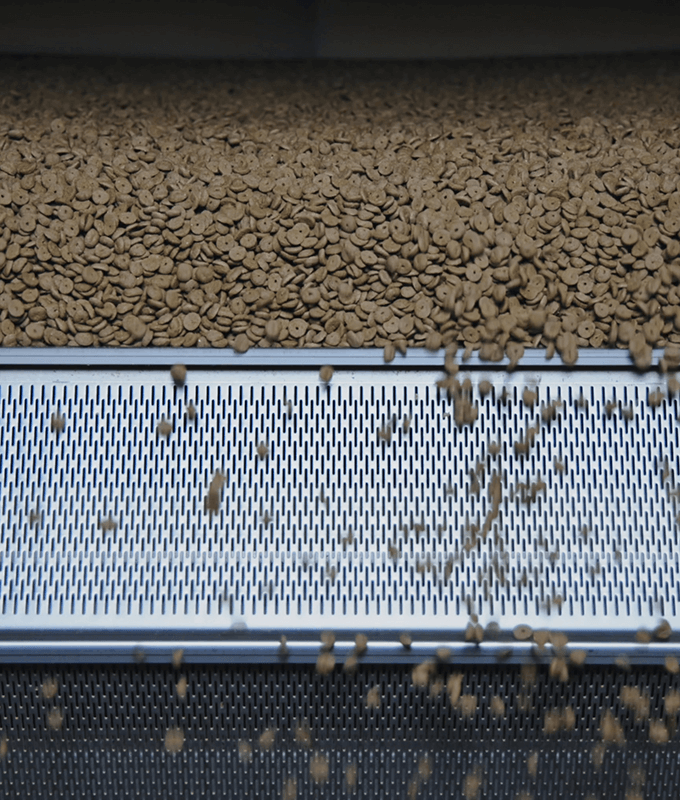

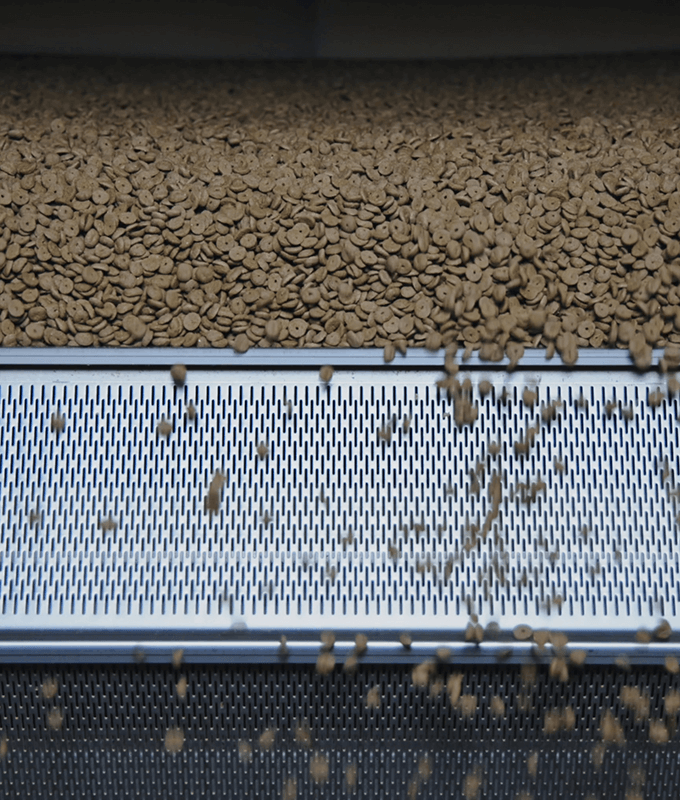

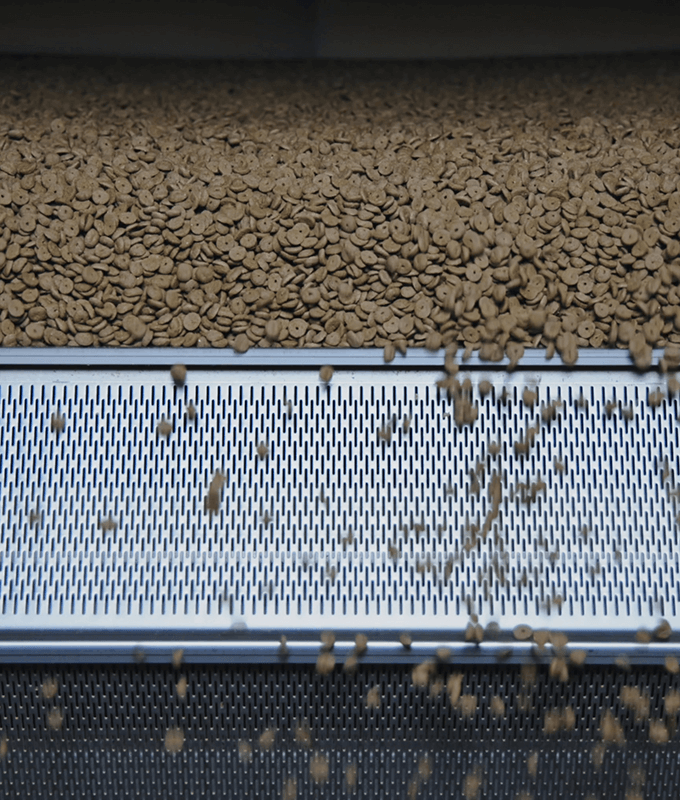

01Excellent Sterilization, Superior Flavor+The baking section employs a high-power, micro-airflow, radiation-based heat transfer solution, eliminating the need for heat transfer media and effectively suppressing the physical phenomenon of "water evaporation endothermic effect". The surface layer of pellets, approximately 0.3mm thick, rapidly dries and heats up to the temperature required for the Maillard reaction in meat, while the internal core temperature rises above the sterilization temperature (74°C) within 5 minutes.

01Excellent Sterilization, Superior Flavor+The baking section employs a high-power, micro-airflow, radiation-based heat transfer solution, eliminating the need for heat transfer media and effectively suppressing the physical phenomenon of "water evaporation endothermic effect". The surface layer of pellets, approximately 0.3mm thick, rapidly dries and heats up to the temperature required for the Maillard reaction in meat, while the internal core temperature rises above the sterilization temperature (74°C) within 5 minutes. -

02High Nutrient Retention+FAMSUN’s Baking and Drying Integrated Machine adopts multi-stage iterative baking and drying technology, with various baking and drying zones. During the high-moisture stage, high-temperature baking and drying are used to cook and sterilize raw materials with low nutrient loss. During the low-moisture stage, low-temperature drying prevents the loss of heat-sensitive ingredient caused by the quick pellet temperature increasing , with the internal core temperature not exceeding 85°C throughout the process (adjustable if high temperature is required).

02High Nutrient Retention+FAMSUN’s Baking and Drying Integrated Machine adopts multi-stage iterative baking and drying technology, with various baking and drying zones. During the high-moisture stage, high-temperature baking and drying are used to cook and sterilize raw materials with low nutrient loss. During the low-moisture stage, low-temperature drying prevents the loss of heat-sensitive ingredient caused by the quick pellet temperature increasing , with the internal core temperature not exceeding 85°C throughout the process (adjustable if high temperature is required). -

03Uniform Moisture Distribution+The material naturally levels itself without a spreader, maintaining the flatness of the forming machine outlet. Combined with CFD-optimized airflow design, energy distribution within the machine is highly uniform. Moisture deviation of the finished product is ≤±0.75%.

03Uniform Moisture Distribution+The material naturally levels itself without a spreader, maintaining the flatness of the forming machine outlet. Combined with CFD-optimized airflow design, energy distribution within the machine is highly uniform. Moisture deviation of the finished product is ≤±0.75%. -

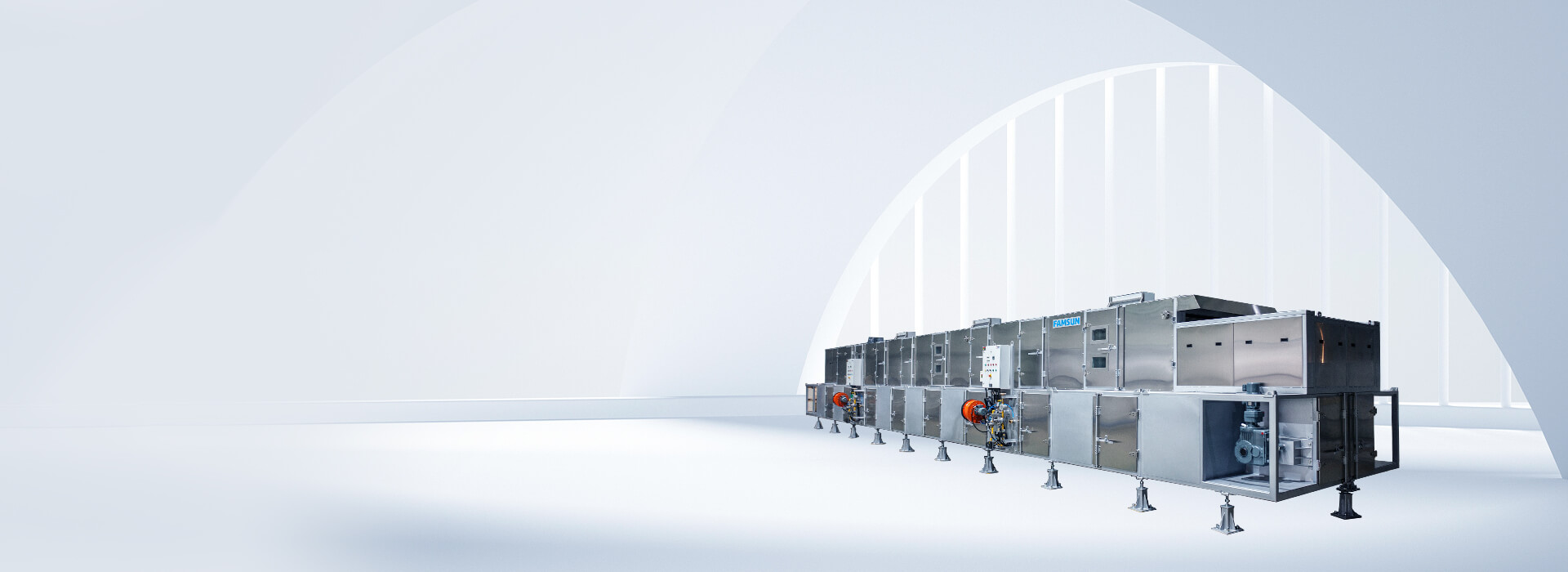

04Cost Savings on Civil Construction+All-in-One-Technology (AIOT) adopts a vertical arrangement structure for the baking and drying machine, shortens the process flow and reduces the length of the factory building. The integrated heat exchange technology eliminates the need for a separate heat exchange unit for dryer, lowering the height of the layout required. The use of reciprocating transport technology shortens the length of the conveying process, further reducing the length of the factory building.

04Cost Savings on Civil Construction+All-in-One-Technology (AIOT) adopts a vertical arrangement structure for the baking and drying machine, shortens the process flow and reduces the length of the factory building. The integrated heat exchange technology eliminates the need for a separate heat exchange unit for dryer, lowering the height of the layout required. The use of reciprocating transport technology shortens the length of the conveying process, further reducing the length of the factory building. -

05Safety and Hygiene+The short process design minimizes intermediate conveying steps, facilitating cleaning and maintenance, as well as ensuring food safety and quality traceability. The gas system, combustion system, and baking and drying integrated machine system, collectively known as the three major systems, incorporate 16 safety measures to ensure safe and stable operation. Large doors and large maintenance space allow for thorough cleaning, mitigating the risk of biological safety hazards due to prolonged residue.

05Safety and Hygiene+The short process design minimizes intermediate conveying steps, facilitating cleaning and maintenance, as well as ensuring food safety and quality traceability. The gas system, combustion system, and baking and drying integrated machine system, collectively known as the three major systems, incorporate 16 safety measures to ensure safe and stable operation. Large doors and large maintenance space allow for thorough cleaning, mitigating the risk of biological safety hazards due to prolonged residue.

Discover our comprehensive after-sales services

and enjoy a seamless experience

We are here to listen

and understand your needs for application solutions

EN

EN